Electric vehicle charging pile production line

summary:

I. Charging pile production line process

The core function of the charging pile is to convert power from the grid into power suitable for electric vehicle batteries and achieve safe and efficient transmission through the charging interface.

II. Core equipment and technology of charging pile production line

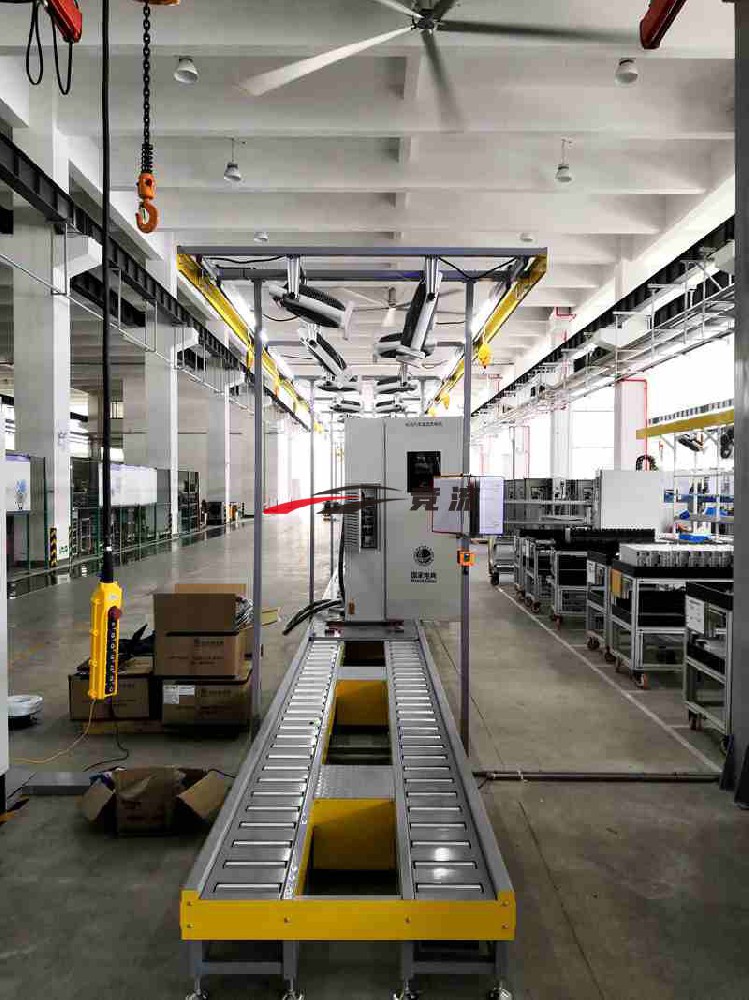

1. automated conveying system

Chain plate line +AGV trolley: Speed adjustable chain plate line (1-10m/min) is used in the assembly area. The area to be inspected is turned 90° by jacking the rotating roller line. The AGV trolley transports finished products to the inspection area according to a preset path. Or warehouse.

Vacuum adsorption robot arm: used for on-line operation of piles above 200kg to improve handling efficiency and safety.

2. intelligent test equipment

Charge and discharge tester: Simulate different battery states to verify the dynamic response ability of the charging pile.

Communication protocol tester: Ensure two-way communication compatibility with BMS (Battery Management System) and power grid.

Vision inspection system: AI algorithms are used to identify appearance defects (such as scratches, color differences) instead of manual visual inspection.

III. Charging pile production line core advantages

Full-process automation system: Equipped with high-precision industrial robots and intelligent conveying systems, it realizes full-process automation from component sorting, precision assembly to performance testing. The average daily production capacity of a single production line can reach 300 + units, which greatly reduces labor costs. Ensure that product consistency errors are controlled within ±0.5%.

Multi-standard compatible design: The production line can flexibly switch global mainstream charging protocols such as European standard (EN 61851), American standard (SAE J1772), British standard (BS 7671), etc. It supports wide voltage output adjustment from 110V to 480V to meet the power grid needs of different regions such as North America, Europe and Southeast Asia, helping customers respond quickly to regional market changes.

Intelligent quality inspection system: Integrate 28 automated testing modules such as infrared thermal imaging testing, withstand voltage breakdown testing, and communication protocol simulation. Each product needs to pass 72 hours of uninterrupted operation testing, and the factory pass rate is stable at more than 99.8%, far exceeding the industry average.

Our electric vehicle charging pile production line has highly automated and intelligent technology. Choosing our charging pile assembly line means choosing to go with the global green travel trend and start an efficient, intelligent and reliable production journey. Let us work together to provide convenient and safe charging solutions for electric vehicle users around the world!

Send Inquiry